Explore the Core of Automation

Every part of our 4-Way Shuttle System is precision-engineered for performance, durability, and full system integration. Dive into each component and discover the technology that powers next-gen warehousing.

Every part of our 4-Way Shuttle System is precision-engineered for performance, durability, and full system integration. Dive into each component and discover the technology that powers next-gen warehousing.

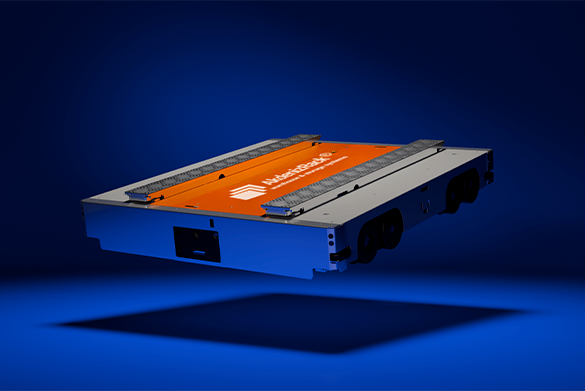

The heart of the system. This autonomous robot travels along both the X and Y axes inside the racking grid, retrieving and depositing pallets or totes with speed and accuracy. With integrated sensors, positioning logic, and rechargeable power systems, it ensures seamless, 24/7 operation.

Fast, high-capacity elevators transport shuttles and goods vertically between storage levels. This enables true multi-tiered warehousing and uninterrupted material flow across floors.

The conveyor system ensures smooth transfer of goods to and from docks, buffering zones, and shuttle lanes. It bridges the gap between automation and manual loading/unloading stations.

Engineered for deep storage and fast shuttle movement, our modular racks are built with precision tolerances, high load capacity, and optimized space utilization in mind.